|

|

■Food Safety

| For a food company, quality control is very important to protect the safety of its products. In order to ensure the safety and reliability of food, Yamazaki Baking has a food safety & hygiene control system founded on scientific basis which deals with bacterial hygiene control, prevention of contamination, and appropriate product labeling.

The Food Safety Division at Yamazaki Baking is responsible for food safety and hygiene training and supervision. The Food Sanitation Control Center within the Division tests ingredients and products, creates and checks product labels, inspects the hygiene of production lines, and educates employees about hygiene.

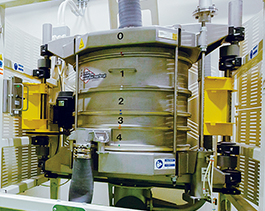

In addition, using the scientific methods of AIB (American Institute of Baking) International Consolidated Standards, the Food Hygiene Control Dept. works with the Food Hygiene Centers at each factory to promote the cleaning, inspection, and improvement of facilities as well as to carry out safety measures focused on preventing contamination.

Furthermore, the Consumer Service draws on inquiries and requests from customers to improve the company’s products. Yamazaki Baking undergoes stringent health and safety management from all possible angles in order to justify its customers’ trust, such as participating in Japan’s newly established Japan Food Safety Standard (JFS Standard) and its certification program. |

|

The American Institute of Baking independently created its AIB International Consolidated Standards based on laws and regulations in Europe and the United States. The goal of the Standards is to eliminate hazards in the factory work environment and in all production processes from the receipt of raw materials to the shipment of products. In 2001, the Japan Institute of Baking established its Food Safety Division and introduced a training and inspection system licensed by AIB and based on its Standards. The system has also been successful outside the baking industry, being introduced at a variety of food production facilities that include those making flour, confectionaries, and dairy products. |

|

|

Ingredients are the heart of the products that Yamazaki Baking provides to our customers. To ensure food safety, we have an extensive inspection system which includes manufacturing plant delivery quality control, temperature controls and etc.

|

|

|

In order to prevent abnormalities in quality due to microorganisms, it is essential to conduct bacteriological examinations of products as well as production line monitoring. Yamazaki Baking has established Food Inspection Offices in its each factories in Japan under the direct control of the company headquarters. Specialized staff sample the products every day and conduct tests to ascertain levels and types of bacteria in order to ensure safety through scientific quality control methods. Furthermore, during the development of new products, prototype samples undergo bacteriological examination, physical and chemical tests, sensory tests, and stress testing. In this way, safety is ensured through the application of a variety of scientific approaches. |

Product labels provide information that prevent accidents related to food hygiene and for customers to make the right decision in selection of the products. Product labels at Yamazaki Baking are checked stringently in order to ensure compliance with related regulations and standards of the Food Labeling Act, as well as to make them easy-to-read and understand for customers. At Customer Service, our dedicated staff courteously provide prompt and accurate information about products and services where inquiries and requests received from customers are utilized to enhance services as well as the development and improvement of products.

|

|

|

|

|